Any car enthusiast from home to the professional restoration company, whether historic or modern race preparation. You will have a use for this low heat input welding process.

We have been Laser Welding modern and historic car parts, ranging from Formula 1 to your rare historic vehicles such as those seen at Goodwood Revival for over 14 years, working along side some of the top historic restoration firms in the country.

The benefits of using Laser Welding over other more conventional means such as Tig, Mig and Electron Beam are as follows:-

1. No pre-heating of the part is required

2. Heat distortion is virtually zero, large areas can be built up without any concern of the part moving, the ability to weld without distortion saves time, and money spent on attempting to recover the part that has distorted therefore no extra machining cost or even the chance of having to scrap the part are involved.

3. The heat effected zone is very small which means the part being welded would not rise above 30°C and the structure of the base material remains the same. This allows any hardening treatment done to the part prior to welding will remain the same.

4. Parts can be welded either before or after hardening with the hardness value of the material being matched or coated with a harder wearing coating.

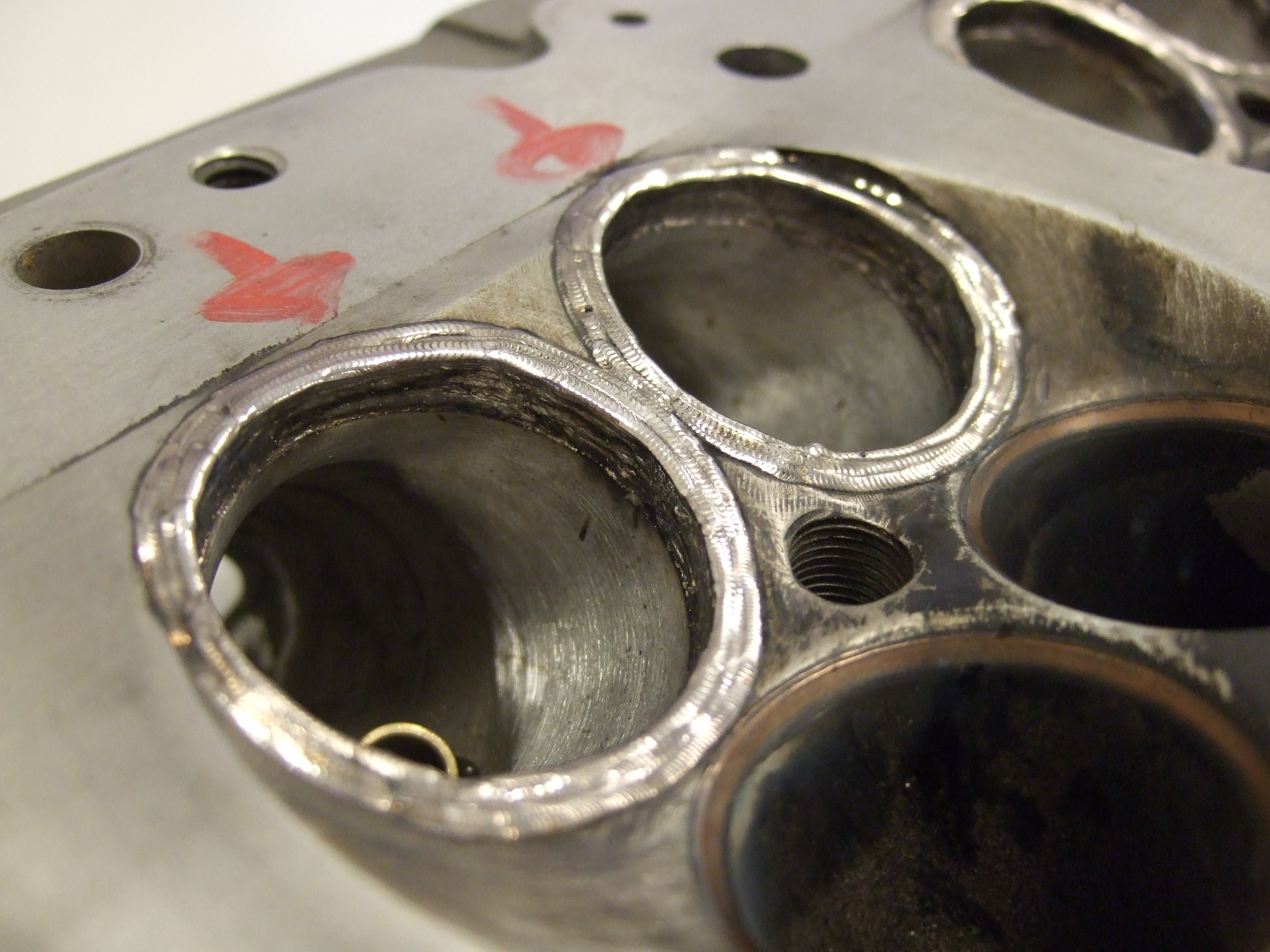

5. Very old and corroded parts can be welded, many historic parts that would normally be beyond normal Tig welding due to the porosity and corrosion can be brought back to life with laser welding.

6. Areas can be accessed that need welding which would be impossible with Tig.

7. A wide range of materials can be welded both ferrous and non ferrous such as

- Aluminium

- Brass

- Bronzes

- Carbon Steels

- Cast Iron

- Copper

- Inconnel

- Magnesium

- Stainless Steels

- Titanium

to name but a few.

There is so much we can do with Laser Welding it really is the repair of the future. In 14 years we have repaired just about anything you can imagine on a historic vehicle.

- Brackets

- Brakes

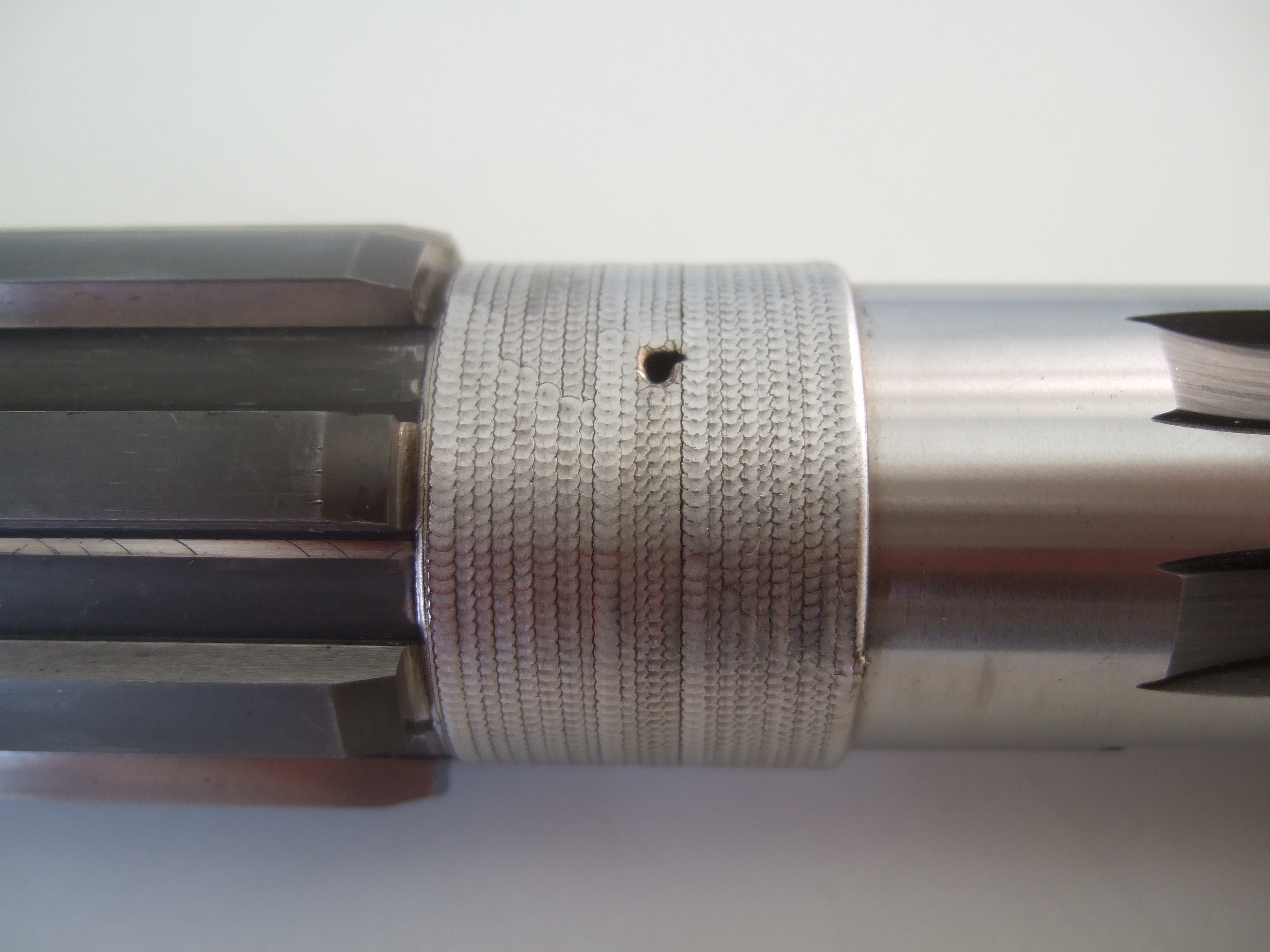

- Cam Shafts

- Car Body Trims

- Clutch Plates

- Con Rods

- Crankshafts

- Engine Blocks

- Followers

- Gears

- Grills

- Heads

- Mudguards

- Radiators

- Tappets

Anything from fusing parts together, build-ups, cracks and water leaks and this is just the tip of the iceberg.

Our team of engineers at EMP Tooling Services are here to advise and overcome any of your welding repair issues, so don’t delay get in touch with EMP today.